With the lower play field given an initial clean and service, it is time to go over the middle area. The main feature of the middle play field area is a central “spinner” (or spinning disk) which rotates constantly during gameplay. It’s covered with a rubber pad used to grip the ball and fling it off (….like a fireball). I won’t be servicing this for now, but will return to it at a later date. The spinner works fine, but really could do with a service.

I will be removing the rest of the mylar up to the pop bumpers, along with servicing the rest of the play field components in that area.

The mylar in the middle section was not as bad as in the lower. But just as with the lower section, someone has attempted to remove parts of it, while leaving the goo and not really doing the best job.

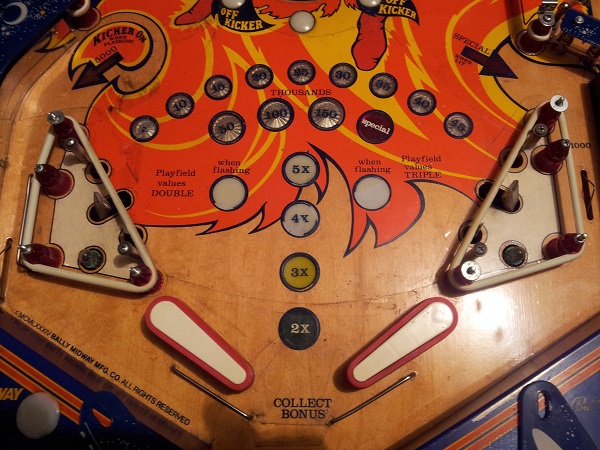

Both sides contain one plastic each, along with some switches, mini mushroom bumpers and a saucer to trap a ball in. The right side also contains a gate which can allow the ball to either return to the shooter lane, or back into play.

(note I had removed the small mushroom bumper on the right side before the starting photo was taken).